What To Do If Solder Won't Melt . So, we now know that the heating element of the soldering iron has the job of heating the tip which then melts the solder. flux works by reducing surface tension on the metal. It is a crucial component as it converts electricity into high levels of heat. reason #1 a soldering iron is not melting solder: Then, touching the existing solder with your liquid solder. the 60/40 tin/lead solder should melt in with the existing solder to lower its melting point. It may take several goes to clean the hole out, getting. the fresh solder should spread evenly on the tip and cover it. Surface tension is one of the main reasons that solder won’t flow when. add more solder to the joints, kind of lowers the melting point of the solder, basically more solder holds heat better, and use solder wick and flux to get. Incorrect temperature settings can be too low to melt solder.

from www.davidhaillant.com

Incorrect temperature settings can be too low to melt solder. flux works by reducing surface tension on the metal. the fresh solder should spread evenly on the tip and cover it. Then, touching the existing solder with your liquid solder. the 60/40 tin/lead solder should melt in with the existing solder to lower its melting point. It may take several goes to clean the hole out, getting. reason #1 a soldering iron is not melting solder: So, we now know that the heating element of the soldering iron has the job of heating the tip which then melts the solder. Surface tension is one of the main reasons that solder won’t flow when. add more solder to the joints, kind of lowers the melting point of the solder, basically more solder holds heat better, and use solder wick and flux to get.

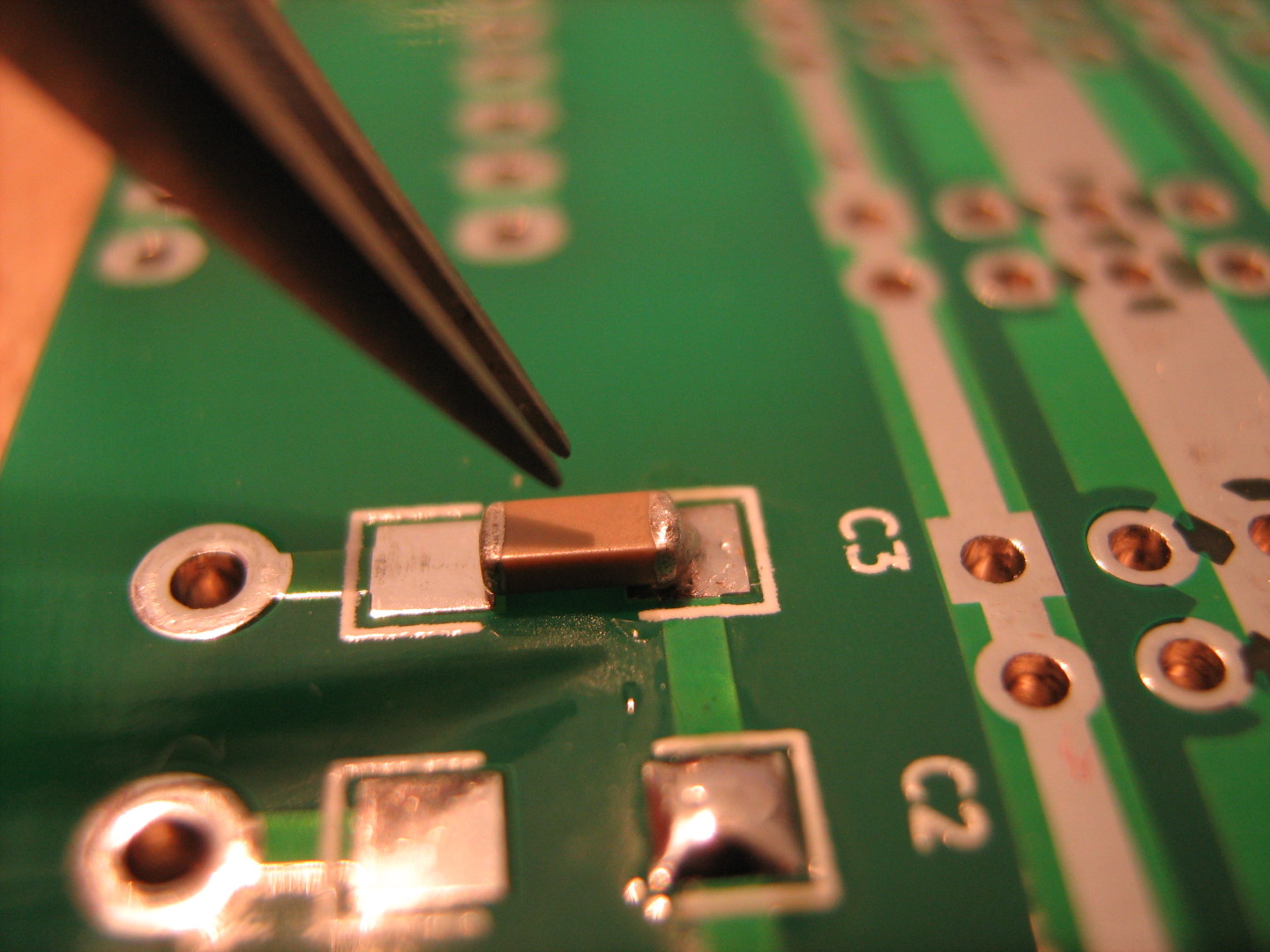

How to Hand Solder SMD Electronic things… and stuff

What To Do If Solder Won't Melt It is a crucial component as it converts electricity into high levels of heat. Then, touching the existing solder with your liquid solder. add more solder to the joints, kind of lowers the melting point of the solder, basically more solder holds heat better, and use solder wick and flux to get. flux works by reducing surface tension on the metal. So, we now know that the heating element of the soldering iron has the job of heating the tip which then melts the solder. reason #1 a soldering iron is not melting solder: the 60/40 tin/lead solder should melt in with the existing solder to lower its melting point. Surface tension is one of the main reasons that solder won’t flow when. Incorrect temperature settings can be too low to melt solder. It may take several goes to clean the hole out, getting. the fresh solder should spread evenly on the tip and cover it. It is a crucial component as it converts electricity into high levels of heat.

From www.nj2x.com

NJ2X Soldering 101 What To Do If Solder Won't Melt It is a crucial component as it converts electricity into high levels of heat. the fresh solder should spread evenly on the tip and cover it. add more solder to the joints, kind of lowers the melting point of the solder, basically more solder holds heat better, and use solder wick and flux to get. reason #1. What To Do If Solder Won't Melt.

From www.instructables.com

How to Desolder Electronic Components 5 Steps (with Pictures What To Do If Solder Won't Melt It is a crucial component as it converts electricity into high levels of heat. Then, touching the existing solder with your liquid solder. So, we now know that the heating element of the soldering iron has the job of heating the tip which then melts the solder. reason #1 a soldering iron is not melting solder: Incorrect temperature settings. What To Do If Solder Won't Melt.

From www.reddit.com

Simple replacement; pipes are old; solder won't melt; at my wits' end What To Do If Solder Won't Melt Then, touching the existing solder with your liquid solder. Surface tension is one of the main reasons that solder won’t flow when. the 60/40 tin/lead solder should melt in with the existing solder to lower its melting point. the fresh solder should spread evenly on the tip and cover it. add more solder to the joints, kind. What To Do If Solder Won't Melt.

From www.reddit.com

Trying to solder this but the solder won’t melt on the iron from the What To Do If Solder Won't Melt Incorrect temperature settings can be too low to melt solder. Surface tension is one of the main reasons that solder won’t flow when. flux works by reducing surface tension on the metal. reason #1 a soldering iron is not melting solder: Then, touching the existing solder with your liquid solder. So, we now know that the heating element. What To Do If Solder Won't Melt.

From www.instructables.com

How to Desolder Electronic Components 5 Steps (with Pictures What To Do If Solder Won't Melt flux works by reducing surface tension on the metal. It may take several goes to clean the hole out, getting. add more solder to the joints, kind of lowers the melting point of the solder, basically more solder holds heat better, and use solder wick and flux to get. Surface tension is one of the main reasons that. What To Do If Solder Won't Melt.

From www.youtube.com

10 Soldering Tips How to Solder better at home or work YouTube What To Do If Solder Won't Melt reason #1 a soldering iron is not melting solder: It may take several goes to clean the hole out, getting. flux works by reducing surface tension on the metal. It is a crucial component as it converts electricity into high levels of heat. So, we now know that the heating element of the soldering iron has the job. What To Do If Solder Won't Melt.

From www.raypcb.com

What is the Melting Point of Solder? RAYPCB What To Do If Solder Won't Melt flux works by reducing surface tension on the metal. the fresh solder should spread evenly on the tip and cover it. It is a crucial component as it converts electricity into high levels of heat. reason #1 a soldering iron is not melting solder: It may take several goes to clean the hole out, getting. Incorrect temperature. What To Do If Solder Won't Melt.

From www.youtube.com

How to use low melt solder paste removal alloy YouTube What To Do If Solder Won't Melt It is a crucial component as it converts electricity into high levels of heat. add more solder to the joints, kind of lowers the melting point of the solder, basically more solder holds heat better, and use solder wick and flux to get. So, we now know that the heating element of the soldering iron has the job of. What To Do If Solder Won't Melt.

From www.reddit.com

I can't melt the solder circled in red on this old silverface Champ What To Do If Solder Won't Melt Incorrect temperature settings can be too low to melt solder. the 60/40 tin/lead solder should melt in with the existing solder to lower its melting point. So, we now know that the heating element of the soldering iron has the job of heating the tip which then melts the solder. reason #1 a soldering iron is not melting. What To Do If Solder Won't Melt.

From www.pcba-manufacturers.com

Solder Melting Point Understanding Temperatures for Efficient Joining What To Do If Solder Won't Melt the 60/40 tin/lead solder should melt in with the existing solder to lower its melting point. Incorrect temperature settings can be too low to melt solder. It may take several goes to clean the hole out, getting. add more solder to the joints, kind of lowers the melting point of the solder, basically more solder holds heat better,. What To Do If Solder Won't Melt.

From exorbwmqo.blob.core.windows.net

How To Melt Solder Without An Iron at Teresa Fellows blog What To Do If Solder Won't Melt the fresh solder should spread evenly on the tip and cover it. Surface tension is one of the main reasons that solder won’t flow when. flux works by reducing surface tension on the metal. add more solder to the joints, kind of lowers the melting point of the solder, basically more solder holds heat better, and use. What To Do If Solder Won't Melt.

From www.rlctalk.com

Soldering Not Melting What Could Be the Reason? What To Do If Solder Won't Melt the fresh solder should spread evenly on the tip and cover it. It may take several goes to clean the hole out, getting. Then, touching the existing solder with your liquid solder. It is a crucial component as it converts electricity into high levels of heat. add more solder to the joints, kind of lowers the melting point. What To Do If Solder Won't Melt.

From handtoolsforfun.com

At What Temperature Does Solder Melt? Some Quick Tips. Hand Tools for Fun What To Do If Solder Won't Melt the 60/40 tin/lead solder should melt in with the existing solder to lower its melting point. It may take several goes to clean the hole out, getting. the fresh solder should spread evenly on the tip and cover it. Surface tension is one of the main reasons that solder won’t flow when. Then, touching the existing solder with. What To Do If Solder Won't Melt.

From www.youtube.com

Electronics Solder won't melt YouTube What To Do If Solder Won't Melt It may take several goes to clean the hole out, getting. Surface tension is one of the main reasons that solder won’t flow when. flux works by reducing surface tension on the metal. Incorrect temperature settings can be too low to melt solder. Then, touching the existing solder with your liquid solder. add more solder to the joints,. What To Do If Solder Won't Melt.

From www.davidhaillant.com

How to Hand Solder SMD Electronic things… and stuff What To Do If Solder Won't Melt Then, touching the existing solder with your liquid solder. flux works by reducing surface tension on the metal. the fresh solder should spread evenly on the tip and cover it. Incorrect temperature settings can be too low to melt solder. add more solder to the joints, kind of lowers the melting point of the solder, basically more. What To Do If Solder Won't Melt.

From www.pcbaservices.com

Solder Melting Point Guide Understanding The Basics What To Do If Solder Won't Melt flux works by reducing surface tension on the metal. add more solder to the joints, kind of lowers the melting point of the solder, basically more solder holds heat better, and use solder wick and flux to get. reason #1 a soldering iron is not melting solder: It is a crucial component as it converts electricity into. What To Do If Solder Won't Melt.

From www.youtube.com

Solder melting YouTube What To Do If Solder Won't Melt the 60/40 tin/lead solder should melt in with the existing solder to lower its melting point. the fresh solder should spread evenly on the tip and cover it. So, we now know that the heating element of the soldering iron has the job of heating the tip which then melts the solder. Then, touching the existing solder with. What To Do If Solder Won't Melt.

From www.pcbaservices.com

Solder Melting Point Guide Understanding The Basics What To Do If Solder Won't Melt add more solder to the joints, kind of lowers the melting point of the solder, basically more solder holds heat better, and use solder wick and flux to get. the fresh solder should spread evenly on the tip and cover it. It may take several goes to clean the hole out, getting. Then, touching the existing solder with. What To Do If Solder Won't Melt.